Scientific advances in

diagnostics and therapeutics have led to the development of more sophisticated

medical devices. These life-changing devices vary in size, geometry,

composition, complexity, and sensitivity to cleaning, disinfecting, and

sterilizing agents.

Manufacturers of

medical devices are required under 21 CFR

801 to support product label claims by providing complete instructions for

handling, cleaning, disinfection, testing, packaging, and sterilization, as

applicable. Manufacturers also have the responsibility to conduct any testing

necessary to validate the suitability of these instructions. Moreover, it is

the manufacturer’s responsibility to consider the feasibility and ease of

cleaning the device in the intended clinical environment when designing their

device.

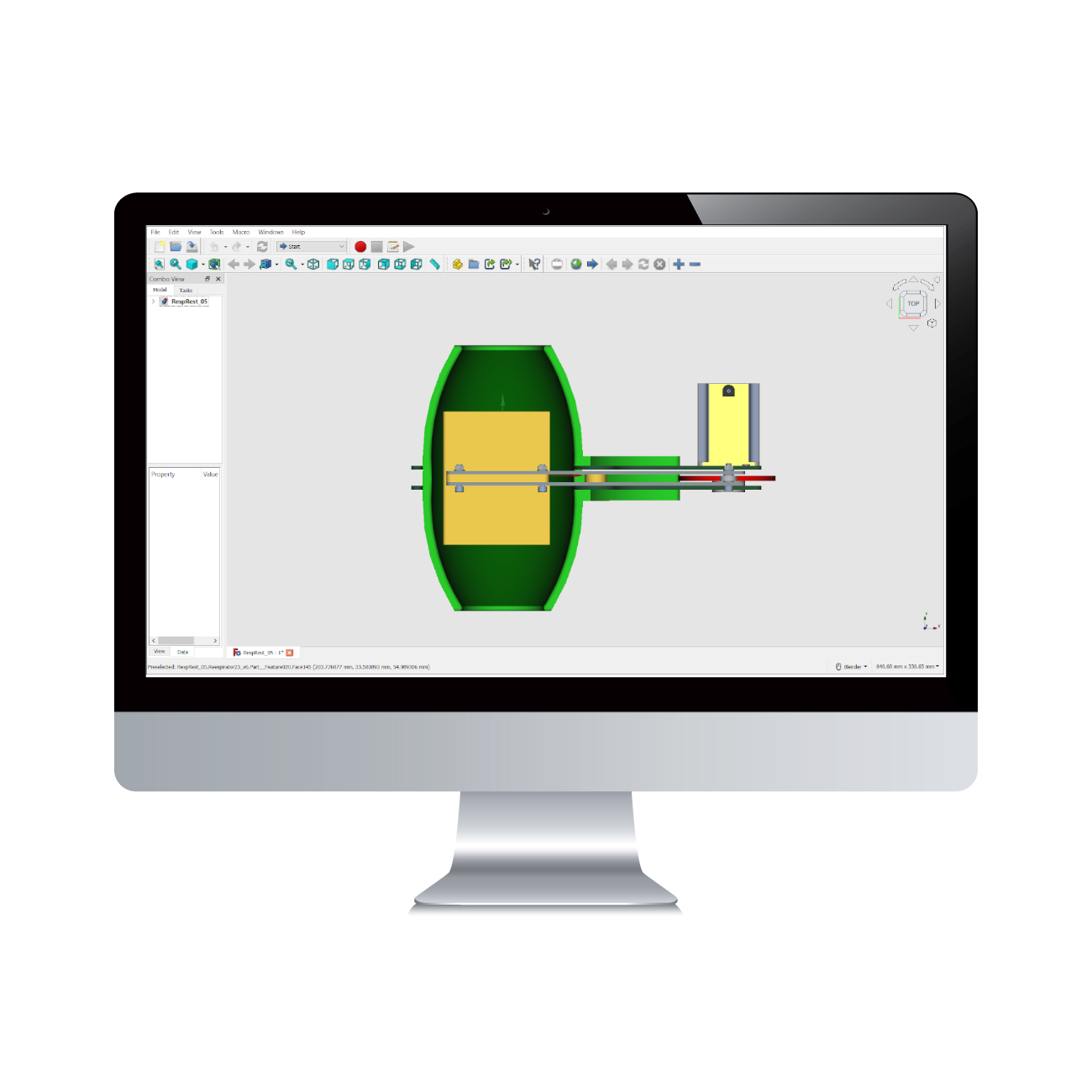

Why is the device design

important from the cleaning perspective?

When performing a

cleaning validation following ANSI/AAMI

ST98:2022, a worst-case use, and conditions must be simulated to represent

the highest challenge to product integrity and safety. This means that the most

difficult areas to clean have to be soiled during the study and then the least

rigorous cleaning process according to the manufacturer’s instructions has to

be applied to remove the soil from the device. If the device has a complex

geometry, hard-to-access crevices, porous surfaces, and a complex disassembly

process, there is a high chance that cleaning and consequently disinfection

and/or sterilization validation will fail, delaying regulatory clearance of the

device.

What factors to consider when

designing a new reusable medical device?

To ensure the

cleanability of a reusable medical device, several major aspects should be considered

during the design process:

1. Risk of patient infection based on intended clinical use: Be aware of the device's classification: non-critical, semi-critical

or critical, as each category will have different requirements from the

cleanability, disinfection, and/or sterilization perspective.

2. Physical design: Design the device with smooth, non-porous surfaces that are easy to

access and clean, while avoiding complex geometries, crevices, and corners

where contaminants can accumulate. When possible, design a fully submersible

device and isolate electronic components. If the device requires disassembly,

ensure the use of the minimum number of components, and an intuitive

reassembly.

3. Material design: Choose materials compatible with common cleaning and disinfecting

agents, and/or sterilization methods. The chosen material should withstand repeated

exposure, without degrading, corroding, discoloring, or losing structural

integrity. Some polymers, for example, offer excellent chemical resistance but

often provide limited heat resistance. In this case, alternatives such as enhancing

the material’s properties, opting for a different polymer or material, or

exploring other sterilization methods, such as ethylene oxide or hydrogen

peroxide should be considered.

4. Total system design: The impact of repeated

cleaning, disinfection, and/or sterilization on the device’s integrity and

functionality should also be evaluated. The use of screws, coating, lubricants,

and glues for example, can limit the cleaning steps, potentially causing the accumulation

of contaminants and consequently impacting the device’s service life.

If your device

incorporates complex design features, there are ways to reduce risk while

enhancing both accessibility and cleanability. Many modern devices include, for

example, ports and channels, O-rings, and articulations. For devices with

channels and ports, it's advisable to provide customized brushes as accessories

and to flush the channels. When O-rings are part of the device, it's important

to establish a routine inspection and maintenance schedule. If the device

features articulations, it should be designed to allow full actuation or

disassembly during the cleaning process.

If you need

consultation regarding the design of your new medical device with a focus on

cleaning, disinfection, and sterilization, don't hesitate to reach out to the SteriLabs’ expert team.

My SteriLabs Experience as an Interdisciplinary Biochemistry and Microbiology Intern. Blog post by Natasha Tal.

September 22, 2025

Microbiologist / Study Lead (Sterilization, Sterility Testing & QMS) — 24-Month Term

September 18, 2025

Media fill testing: Ensuring Aseptic Processing for Client Projects and Licence Applications. Blog Post by Natasha Tal

August 22, 2025