In

the microbiology world, culture media serves as the base of all research and

discovery. These bacteria-loving recipes create the perfect environment for surviving

microorganisms to grow by providing the necessary nutrients in their

composition. The ingredients vary depending on the microorganism being studied but

creating culture media is straightforward. However, the quality control

measures associated with it are often neglected, although it is fundamental to

accurate and reproducible results as per ISO 17025 accreditation requirements.

Why

is quality control so important when it comes to culture media? In every

sterilization validation, there are two main components which include the

bacteria and the culture media. Improper media preparation can cause

unsatisfactory conditions for the growth of surviving microorganisms and can

lead to unreliable results.

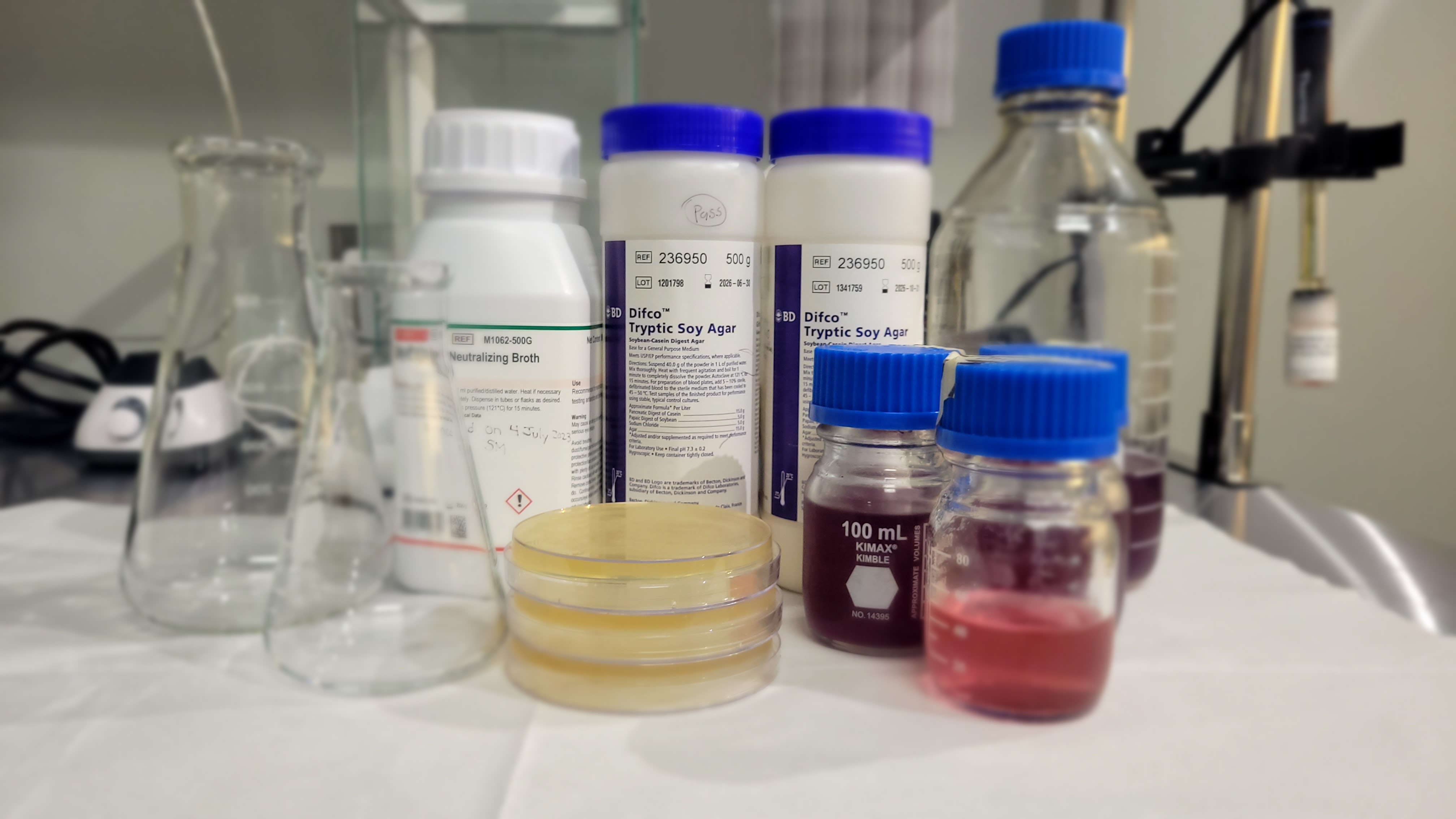

High-quality

media is required to have confidence in the accuracy and validity of a

sterilization validation study and its results. There are quality control tests

that must be routinely performed on all prepared media to ensure that each

batch of media satisfies the requirements for a supply of high-quality in-house

prepared media.

After

the culture media is prepared it is essential that it is sterilized to

eliminate any existing and unwanted microorganisms. This can be achieved

through autoclaving at a validated cycle using heat and pressure to kill any microbial

life. Along with sterilization, there are key quality control steps that can be

taken by conducting the following:

Growth Promotion test which tests the medium’s ability

to support the growth of the bacteria needed for the validation of the

specified sterilization modality. This is done by inoculating a population of

less than 100 viable organisms onto the media and monitoring for growth. The

productivity ratio for a non-selective medium is at least 70% for positive

strains when compared to the reference medium indicating a successful growth

promotion test.

pH test is another crucial test that can be conducted,

as different microorganisms thrive under different conditions. Each type of

media has a different acceptable pH range that it must fall within in order to

support the growth of the specific microorganism.

Visual Inspection confirms the quality of the medium as

it should be clear and free from deformation, turbidity, or discoloration. Any

of these irregularities can indicate contamination or poor-quality media.

Another

way to ensure media is prepared to the highest quality is that when handling

with microorganisms and culture media it is of the utmost importance to

practice aseptic techniques – conditions and procedures used to minimize the

risk of the introduction of microbial contamination. Not only is this important

for controlling contamination but also for biosafety.

As

the foundation of microbiological testing, maintenance, and storage under

validated conditions is critical to keep its quality preserved. For agar plate

storage, it is good practice to place them in a sealed package to reduce

moisture loss. It should never be frozen as this can cause damage to the gel

structure. All prepared culture media should be labeled with the media name,

batch number, preparation, and expiration date as well as the name, or

initials, of the person who prepared it prior to being placed in validated

storage conditions.

As

long as these steps are taken into consideration during media preparation and

storage, a consistent supply of media optimum for recovery of microorganisms

during sterilization cycle validation can be attained.

My SteriLabs Experience as an Interdisciplinary Biochemistry and Microbiology Intern. Blog post by Natasha Tal.

September 22, 2025

Microbiologist / Study Lead (Sterilization, Sterility Testing & QMS) — 24-Month Term

September 18, 2025

Media fill testing: Ensuring Aseptic Processing for Client Projects and Licence Applications. Blog Post by Natasha Tal

August 22, 2025